Automated Manufacturing Facility

E. Hofmann Plastics

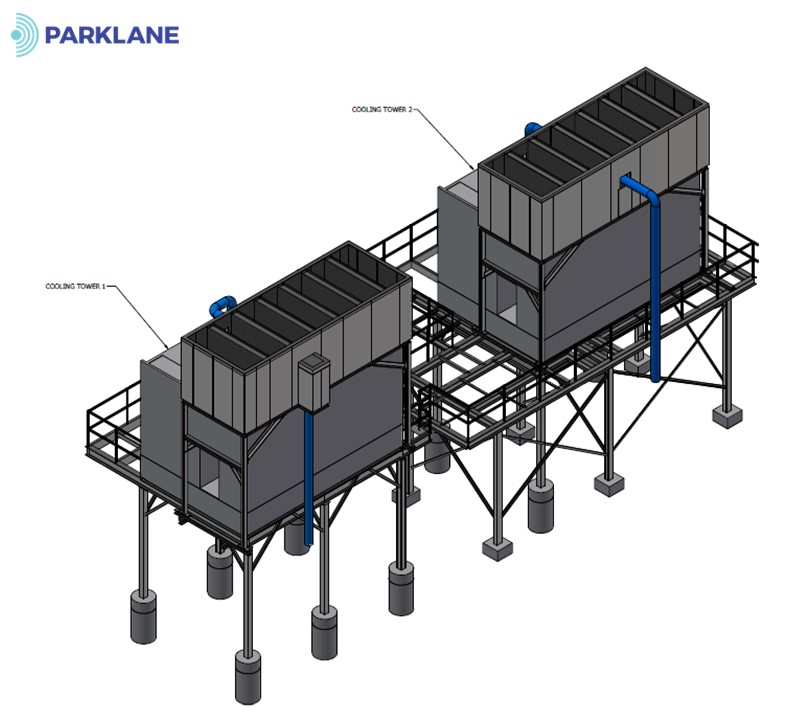

Design, fabrication, and installation of two acoustic plenum silencers and structural support to mitigate noise from a pair of new cooling tower exhaust fans.

Overview

E. Hofmann Plastics has been a mainstay in plastics manufacturing for twenty-five years, but when they updated their automated manufacturing facility, they began to receive complaints from the local community that the noise from their new cooling towers exceeded local municipal bylaws. Parklane was brought in to craft a custom solution that would attenuate the noise without impacting the efficiency of the cooling system.

The Project Facility

Automated Manufacturing Facility

The Noise Source

Two Cooling Tower Exhaust Fans

The Solution

Acoustic Plenum Silencers

The Project Team

Owner

Reason for Mitigation:

Municipal noise bylaw; Compliance with local regulatory limits for exterior noise emissions

Project Challenges

Support Structures

The cooling towers and equipment were raised up on an existing structural platform at the rear of the facility. Parklane’s engineers discovered that the existing support structure was not strong enough to carry the weight of the new acoustic plenums. After careful consideration, it was determined that additional support would need to be installed to ensure that the plenums could be securely installed without their weight causing damage to the cooling towers.

Mechanical Interferences

The pipes supplying liquid to the cooling towers were originally slated to be disconnected for construction. To prevent interruption to operations, the facility owner requested that it remain connected and active throughout the installation process. This meant that the pipe could not be removed in order to install paneling around it or in any way impeded by the paneling.

Project Solution

Design

Parklane designed two custom acoustic plenum silencers with accompanying structural support to bring the facility into regulatory compliance. To manage the increased weight on the structural platform, Parklane’s engineering team created a design to reinforce the platform with high-strength structural steel, hot dip galvanized to prevent corrosion. This additional support ensured that the newly imposed loads could be effectively supported without stress on the existing equipment.

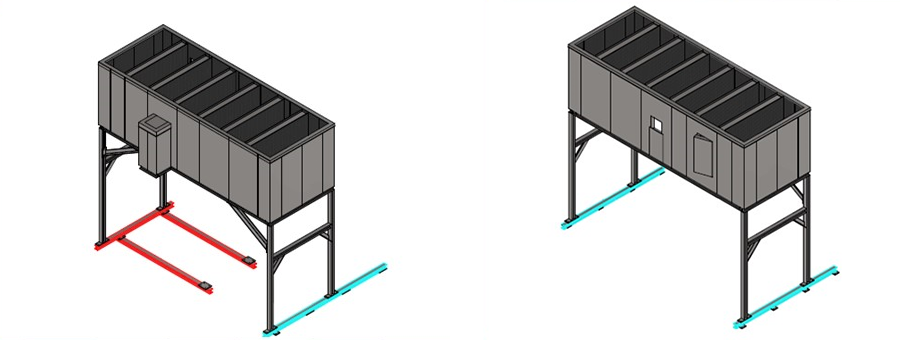

In lieu of disconnecting the pipes, Parklane adjusted the final design so that the finishing panel could be notched and installed around the pipe fixtures while allowing it to remain operational.

Modular Construction

The solution was entirely pre-fabricated in two modular assemblies, which created significant advantages for the overall construction process. The pre-fabrication process ensured a higher level of quality control, as each assembly could be thoroughly inspected and tested prior to transport, allowing for a faster and more efficient installation on-site. The modular design also provided the flexibility to make required adjustments, removing potential site complications and reducing the original project schedule significantly

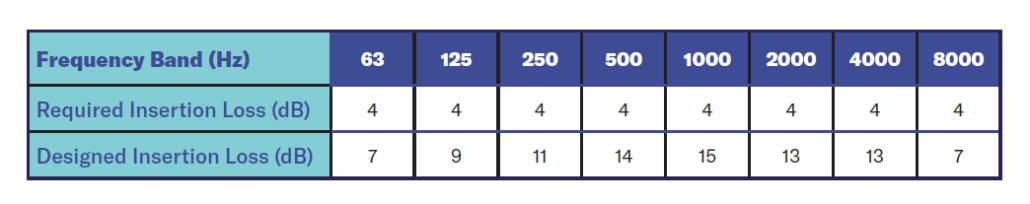

Aero-Acoustic Performance

Significant attenuation was required to bring the facility into compliance; however, the efficiency of the cooling system had to be maintained. A “low static” design was used for the plenum silencers, ensuring that compliance could be reached without impacting cooling performance. The aero-acoustic tables show the mitigation achieved at project completion.

Results

The final design was so precisely fitted, and Parklane’s team was so efficient in their forethought and careful planning that the installation was done over a month ahead of schedule. The final solution performed optimally and brought the cooling towers condensing fans well into compliance with regulatory limits.

Read the full story

Learn more about how we mitigated Hofmann’s noise emissions without impacting facility performance.

Let's work together

Contact a member of our team now to find out how Parklane can help provide an effective, customized solution to your organization’s noise control challenges.