Industrial Manufacturing

Food Production Facility

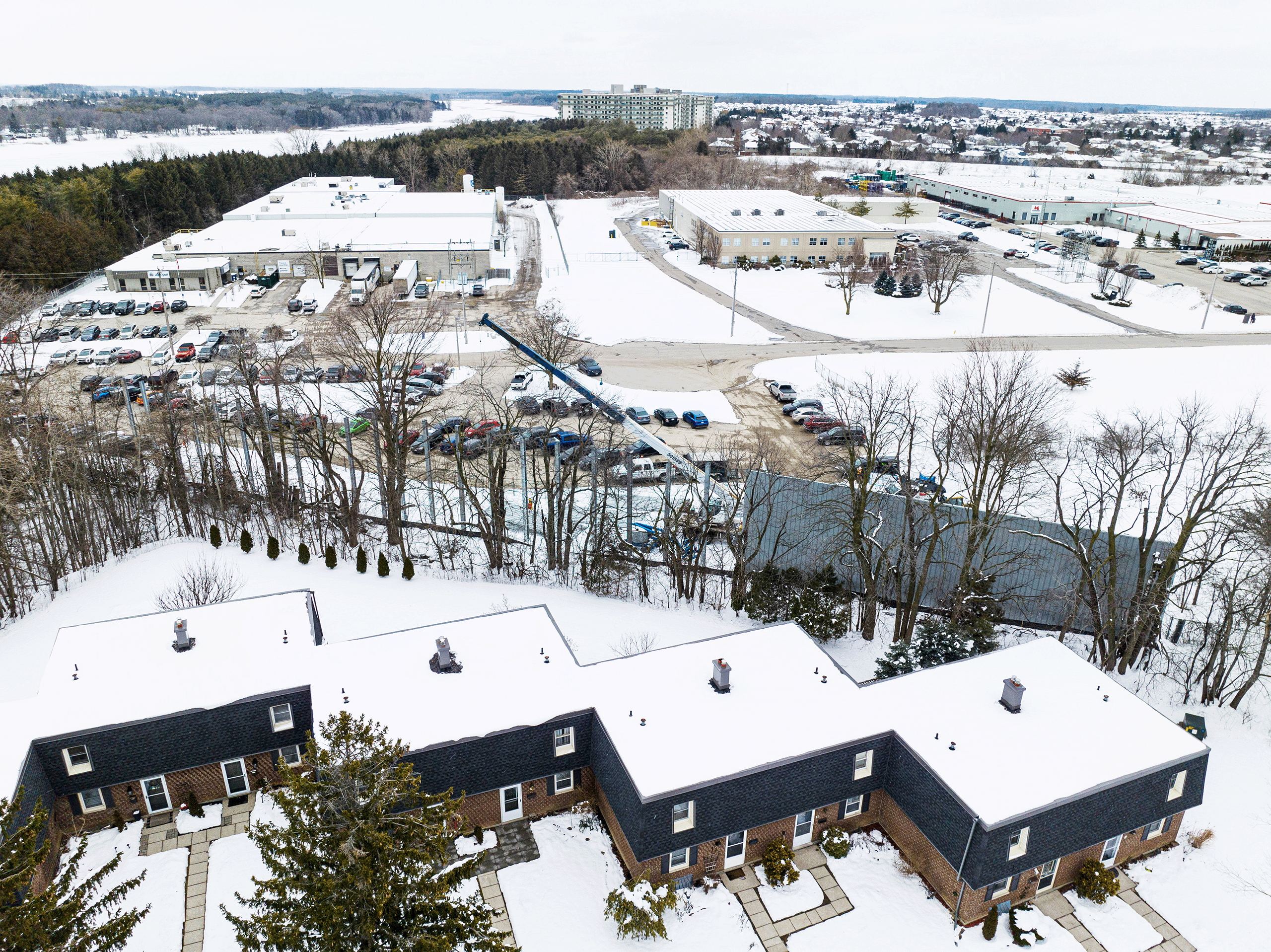

A prominent food production facility in the industrial production sector, sought a comprehensive solution to achieve site-wide compliance with provincial noise regulations. The project addressed noise generated by on-site refrigerated truck traffic and various industrial processes through the installation of a modular acoustic-grade barrier.

Overview

This large-scale food and beverage company operates a busy industrial production facility where compliance with provincial noise regulations is crucial. Faced with noise issues from refrigerated truck movements and a range of complex industrial processes, the client partnered with Parklane and Aercoustics to develop an innovative, modular acoustic-grade barrier solution. This collaborative build project and custom design was undertaken to ensure regulatory compliance without sacrificing operational efficiency or aesthetic appeal for the surrounding community.

The Project Facility

Industrial Production

The Noise Source

On-site Refrigerated Truck Traffic and Miscellaneous Industrial Processes

The Solution

Acoustic Grade Barrier (Modular)

The Project Team

Acoustic Engineer – Aercoustics

Owner – Food Manufacturing Company

Reason for Mitigation:

Compliance with provincial noise regulations.

Project Challenges

Balancing Compliance with Operations

The Client needed to mitigate noise levels to meet strict provincial standards while preserving the operational flexibility of its facility. With multiple truck bays in constant use, the challenge was to integrate a solution that effectively reduced noise without disrupting the facility’s essential workflow.

Collaborative Design-Build Coordination

Without the involvement of a mechanical consultant or general contractor, the project required a tight-knit, cross-disciplinary team. Parklane, The Client, and Aercoustics collaborated closely as a design-build team. This integrated approach was critical for optimizing the noise barrier’s performance, keeping the project on budget, and adhering to a strict schedule—all while achieving full compliance.

Complex Engineering and Site Constraints

The project’s unique demands necessitated an in-depth engineering approach. From conducting geotechnical analysis and designing concrete foundations to integrating structural and architectural elements, every facet of the site’s conditions had to be addressed. These technical challenges were crucial to ensuring the long-term durability and effectiveness of the acoustic grade barrier.

Project Solution

Design

Acoustical Analysis and Sound Propagation Modeling:

Aercoustics performed comprehensive on-site acoustical analysis and sound propagation modeling to define the optimal specifications and placement of the acoustic-grade barrier.

Integrated Engineering Approach:

The project included detailed geotechnical analysis, concrete foundation design, structural engineering, and architectural planning. This multidisciplinary approach ensured that the barrier met both performance and compliance standards.

Fabrication Detailing:

Extensive fabrication detailing was completed to refine the modular design, ensuring that the barrier could be manufactured efficiently and installed with precision.

Installation

Manufacturing and On-Site Assembly:

The modular acoustic barrier was manufactured to exact specifications and installed on-site with a focus on minimizing operational disruptions.

Site Management and Restoration:

Parklane oversaw the entire installation process, from foundation work to the final assembly, including comprehensive site management and the complete restoration of the surrounding area, ensuring a seamless integration with existing infrastructure.

Community Response

Aesthetic Integration:

Beyond noise mitigation, the solution was designed with aesthetics in mind. The barrier not only met compliance standards but also enhanced the visual appeal of the facility, addressing concerns from neighbouring residences.

Positive Impact on Operations and Neighbourhood:

The project’s success was measured by its dual impact: optimizing facility operations by allowing extended truck bay accessibility while simultaneously reducing noise impact for the local community.

Results

The project delivered a robust noise mitigation solution that enabled The Client to achieve full compliance with provincial noise regulations. The modular acoustic-grade barrier effectively reduced noise emissions, allowing the facility to utilize multiple truck bays for longer periods without exceeding permitted noise levels. In addition to enhancing operational efficiency, the aesthetically pleasing design of the barrier improved relations with neighbouring communities by minimizing disruptive noise impacts. This case study exemplifies how strategic collaboration and a comprehensive design-build approach can yield solutions that effectively meet technical, operational, and community needs simultaneously.

Read the full story

View the full write up to learn more about how we helped this food production facility get noise compliant.

Let's work together

Contact a member of our team now to find out how Parklane can help provide an effective, customized solution to your organization’s noise control challenges.