A Custom Generator Enclosure Case Study

Lakeridge Health

Our customer on this project is a energy specialist providing complex interconnected energy systems. As part of an Integrated Energy Performance Contracting (IECP) program for Lakeshore Health in Oshawa, Ontario, an on-site power plant was engineered to generate electricity for peak-power-offset, as well as heat recovery. The heart of the system – two 800Kw generators – each required acoustic treatment.

Project Challenges

Site Access

The main project constraint was transporting the enclosures to each generator, which were located deep within the hospital’s basement. The only access was an overhead hatch more than 100 feet away, requiring each enclosure to fit through a hole a fraction of its assembled size.

Aside from difficult access, significant forced air ventilation, perimeter access, roof access, seismic loading and a sound pressure level (SPL) of 78dB (at 1m) needed to be accounted for and addressed.

Project Solution

Modular Design

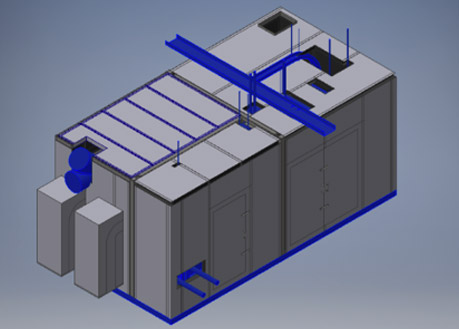

Our project manager worked closely with the customer to identify and measure all design constraints from site-access to enclosure-penetrations to structural issues. With this information in mind – as well as the primary design parameters (sound, ventilation, access) – our designer created two site-specific modular enclosures that were completely built, tested for fit, disassembled, and packaged in our shop. Once on site, each enclosure section was carefully reassembled by our field-service crew.

- A fully modular enclosure

- Complete 3-D model for base enclosures and site-interferences (gas/electrical feeds)

- 4.5” HTL acoustic panel selected to achieve SPL of 78dB (at 1m)

- Removable acoustic plug roof panels for engine removal

- Single / double door access provided to all critical components

- Air ventilation (20°F differential across the enclosure), without sacrificing acoustic performance

- Interior LED lighting

- 4.5” HTL acoustic panel selected to achieve SPL of 78dB (at 1m)

- Pre-finished steel construction for architectural appeal

- 4.5” HTL acoustic panel selected to achieve SPL of 78dB (at 1m)

- 4.5” HTL acoustic panel selected to achieve SPL of 78dB (at 1m)

Results

Aside from successfully addressing the primary design constraints of sound attenuation, ventilation and equipment access, the innovative site-integrated approach used by Parklane delivered a cost-effective, timely solution for a challenging, site-constrainted project.

Let's work together

Contact a member of our team now to find out how Parklane can help provide an effective, customized solution to your organization’s noise control challenges.