A Modular Roof Screen Case Study

Rogers Head Office

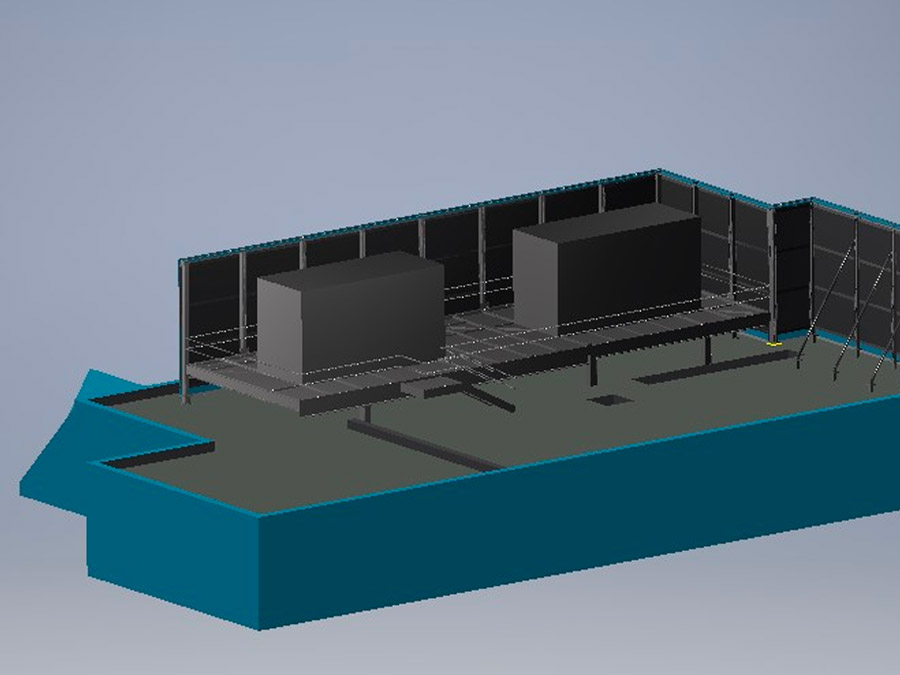

Located in the heart of downtown Toronto, Rogers Communications headquarters was retrofitted with a state-of-the-art data centre and the associated rooftop chillers/cooling towers. With residences across the street sharing the block with the Rogers building, a 15’ tall acoustic barrier surrounding the chillers was required to bring the site into compliance according to MOECC NPC 300.

Project Challenges

Time

The timeline for assembly and installation was very compressed compared to a typical roof screen project: less than a week to factory-assemble 16 wall sections and one day (10 hours) to install all 16 sections on a roof three stories above a busy Toronto street.

Logistics

A mix of city by-laws, last-minute design changes and pre-installation site coordination made this project more challenging than most.

Project Solution

Site Preparation

Pre-installation of the stub columns (preceding the roofing by hours) needed to be done carefully to ensure an exact match to the screen sections that were being produced simultaneously at our manufacturing facility. If these stub columns weren’t in the right place, it would have been impossible to complete the barrier installation in one day.

Logistics

Since there was no room for staging, the 90T crane had to be set up in Rogers’ shipping/receiving entrance allowing two 48’ flatbeds to pull up beside the crane. Each truck carried eight wall sections, which were offloaded directly and lifted to the roof. On the day of the installation, there were eight Parklane personnel, two general contractor representatives, three paid-duty officers, two traffic control personnel, one crane operator and two truck drivers. All bases were covered.

Modularization

At the core of every Parklane project is our modular approach to product design. The solution for the Rogers job was to design 16 different wall sections to precisely match each set of site-installed stub columns. To ensure a quick and successful installation, tight tolerances (within fractions of an inch) were incorporated into the design.

Results

Careful planning and coordination from beginning to end were the keys to success. Although the saying goes that the best laid plans often go awry, all 16 sections were installed on time and without any further disruptions to Rogers and its neighbours (despite the 3°C temperature and pouring rain).

Let's work together

Contact a member of our team now to find out how Parklane can help provide an effective, customized solution to your organization’s noise control challenges.