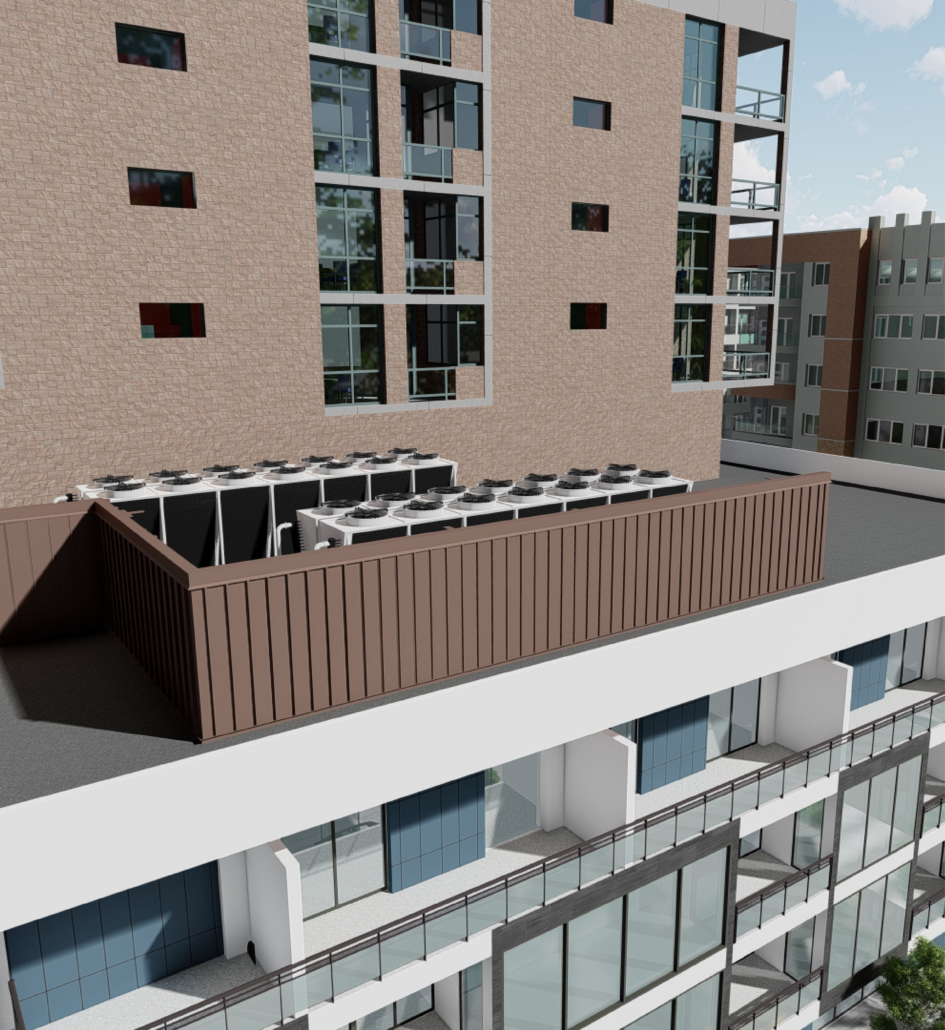

Acoustic Barriers

Acoustic barriers are the go-to solution for effective sound attenuation, designed to reduce noise from various sources in a specific area. Parklane’s industry-leading Acoustic Screens & Barriers offer a range of customizable options, each tailored to meet unique acoustic requirements, structural needs, and aesthetic considerations. Thanks to their innovative modular design, these barriers can effortlessly transition into standard architectural screen systems, providing both functionality and style.

Key Features

Parklane’s Acoustic Screen and Barrier Systems are fully adaptive to any site environment, ensuring seamless integration to any building - new or existing.

Lab Validated Acoustic Performance

Our acoustic screens, including absorptive acoustic panels and louvered styles, deliver lab-tested performance that meets rigorous ASTM and AMCA standards. Their effectiveness is further ensured through advanced in-house computational modelling, providing reliable noise control solutions for any application.

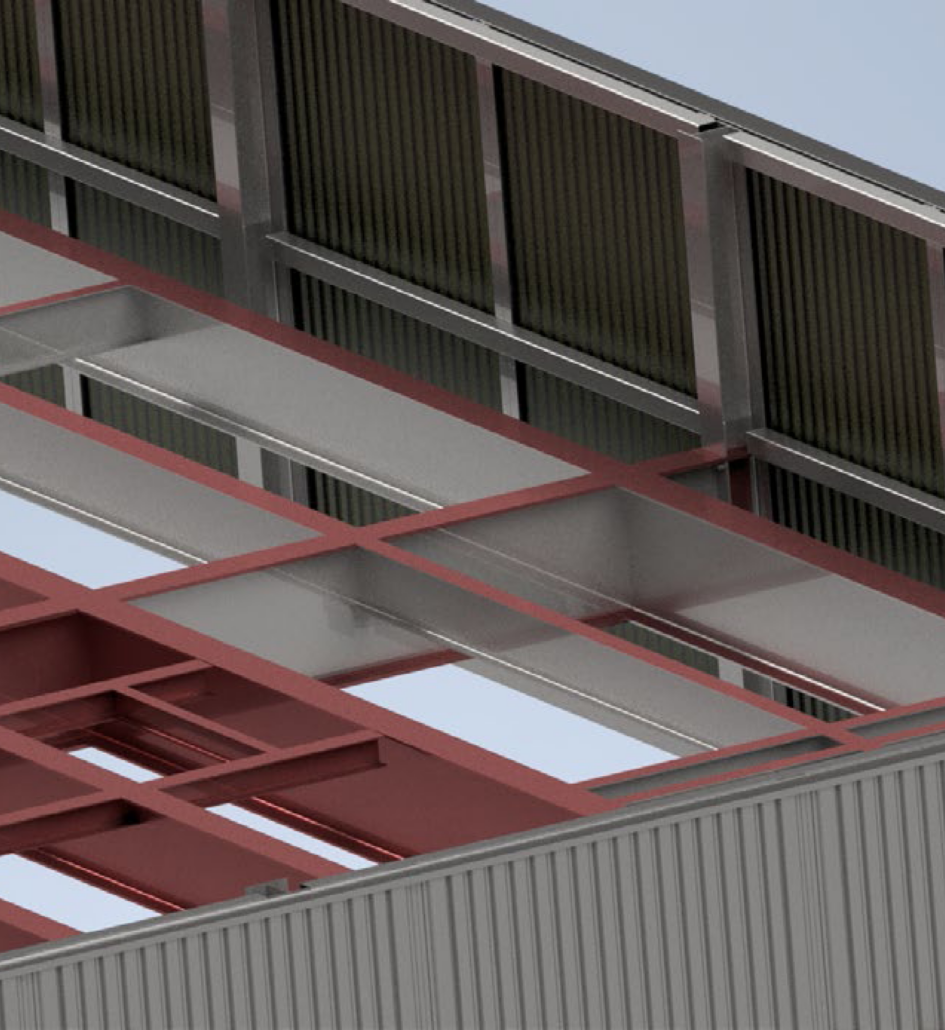

Complete Aesthetic Flexibility

Our acoustic screens offer unparalleled aesthetic flexibility, allowing architects to apply virtually any cladding system to the exterior façade. This empowers complete creative control over the final design, ensuring seamless integration with the architectural vision.

Pre-Fabrication and Modularity

Our acoustic screens feature prefabricated modular construction, integrating structural, acoustical, and architectural elements into a single system. This streamlined approach enhances quality, simplifies installation, and significantly accelerates project timelines.

Customized Site Integration

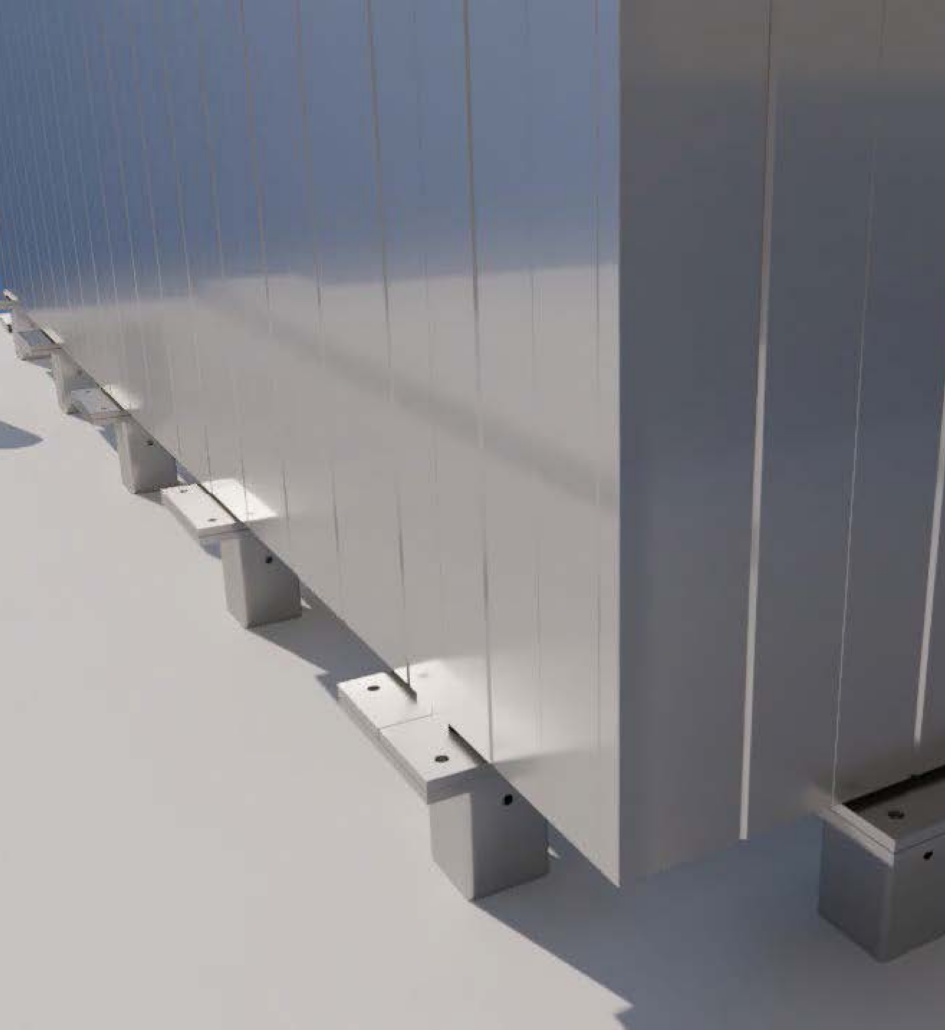

Parklane Acoustic Barriers are engineered to work within site-specific structural challenges to ensure seamless integration in both structurally affixed and non-penetrating installations.

Aesthetics and Acoustics

Thanks to their modular design, Parklane’s screening systems can effortlessly transition from acoustic to purely visual by removing acoustic elements where noise control isn’t needed. This provides flexibility to balance aesthetics and acoustics without compromising design consistency.

Modular Solutions for Any Application

Available in a variety of configurations, each specifically engineered to accommodate site-specific acoustic criteria, structural configuration, and architectural appeal.

Acoustic roof screens are designed to form a rigid connection that seamlessly interfaces with any roof structure, available with absorptive acoustic panels or louvered designs for effective noise control and architectural integration.

Acoustic grade barriers are securely mounted to on-grade foundations, offering durable noise mitigation with options for absorptive panels or louvered styles, designed to withstand environmental conditions.

Gravity Barriers™ are our proprietary self-supporting acoustic solutions, engineered to minimize or eliminate the need for rigid connections to your building’s roof, ensuring flexibility, ease of installation, and reliable noise control.

Mounting Options

The Parklane Acoustic Screening System can be easily adapted to any aesthetic building feature or structural constraint—no matter the complexity. It’s modular engineered design offers complete flexibility without diminishing acoustic performance, making the Parklane Acoustic Screen the ideal solution for any rooftop or on-grade application.

Clip-Mounted

Screen panels are mechanically affixed to existing structural steel elements ensuring direct-load transfer and integration with the building’s structural system.

Stub-Mounted

Screen assemblies are supported on engineered steel stub columns, which are mechanically anchored to the roof structure to provide independent structural support without reliance on adjacent enclosures.

Gravity Restrained

A non-penetrating, ballasted solution that maintains structural stability through distributed weight, preserving the integrity of the roof membrane and eliminating the need for roof penetrations.

Acoustic Options

Absorptive Acoustic Panel

Parklane offers several performance options for both Transmission Loss and Wall Absorption, all tested in accordance ASTM E90 and C423 standards.

Acoustic Louver

Parklane offers several performance options for both Transmission Loss and Open Free Area, all tested in accordance ASTM E90 and AMCA 500-L standards.

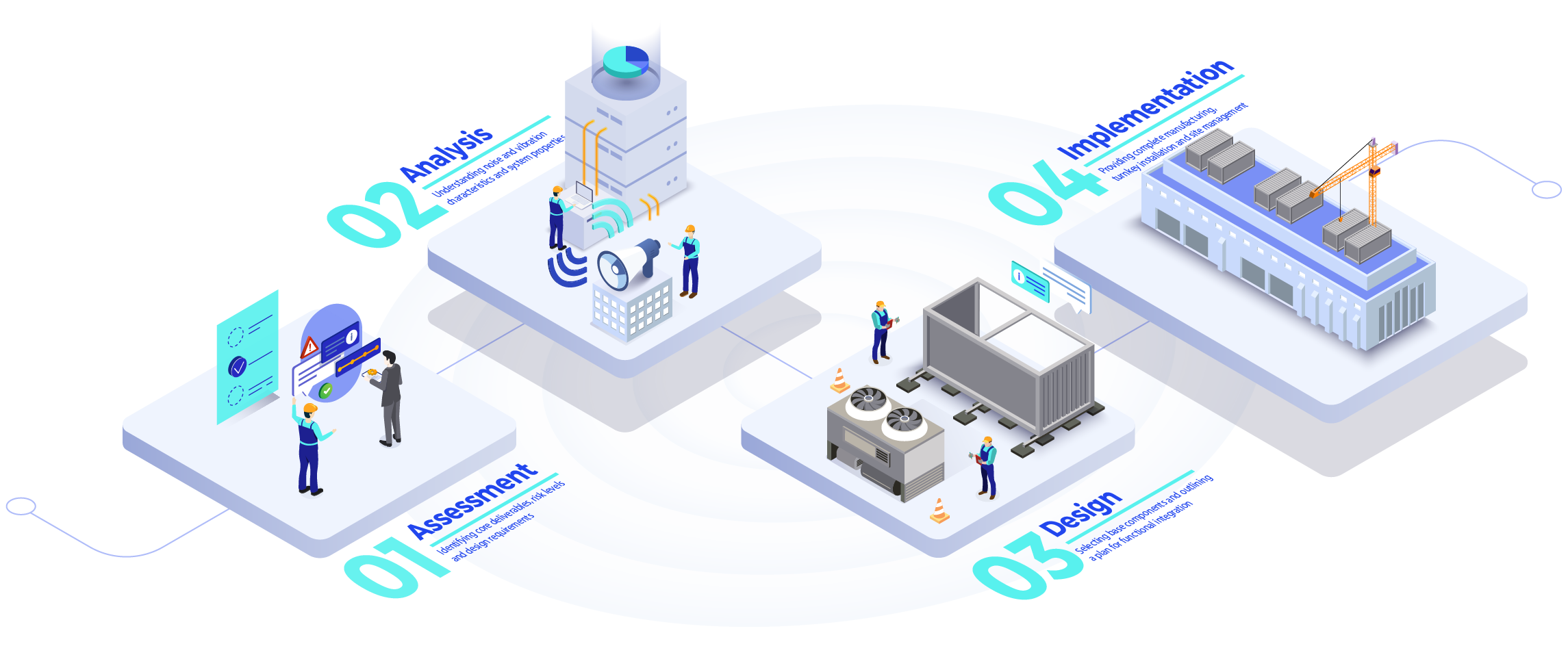

Solving your complex challenges

By taking a fully integrated approach to every project, we leverage our team’s engineering expertise, a commitment to quality product manufacturing and a service-focused delivery model to help mitigate non-compliance risk and deliver the results you expect—every time.

Learn more about:

Success Stories

We’ve helped a wide range of clients mitigate complex noise and vibration control challenges

Read a selection of our success stories

Industrial Food

Production Facility

Modular Grade Barriers for refrigerated truck traffic and industrial process attenuation

Rogers Head Office

Modular roof screen and an acoustic barrier retrofit to the rooftop of a large-scale downtown office high-rise building

501 Lakeshore -

Mixed-Use Facility

Gravity barriers for all equipment on two mixed-use buildings in close proximity to residential property.