Every life-changing scientific advancement needs a hub where it’s first conceived, tested, perfected and then debuted to the world. Botterell Hall at Queen’s University in Kingston, Ont., is one of those spaces.

The nine-storey building is home to the school’s Centre for Neuroscience Studies and plays host to advanced heart, stroke and cancer research. It, and buildings like it, are the backbone of Canada’s research and development sector—and their uninterrupted operation is vital.

So, when Queen’s administrators decided to renovate the world-class biochemistry research facility—which was first constructed in 1979 and required significant retrofits to help strengthen the university’s standing as a leader in the field—they understood it would be an extensive and highly involved process.

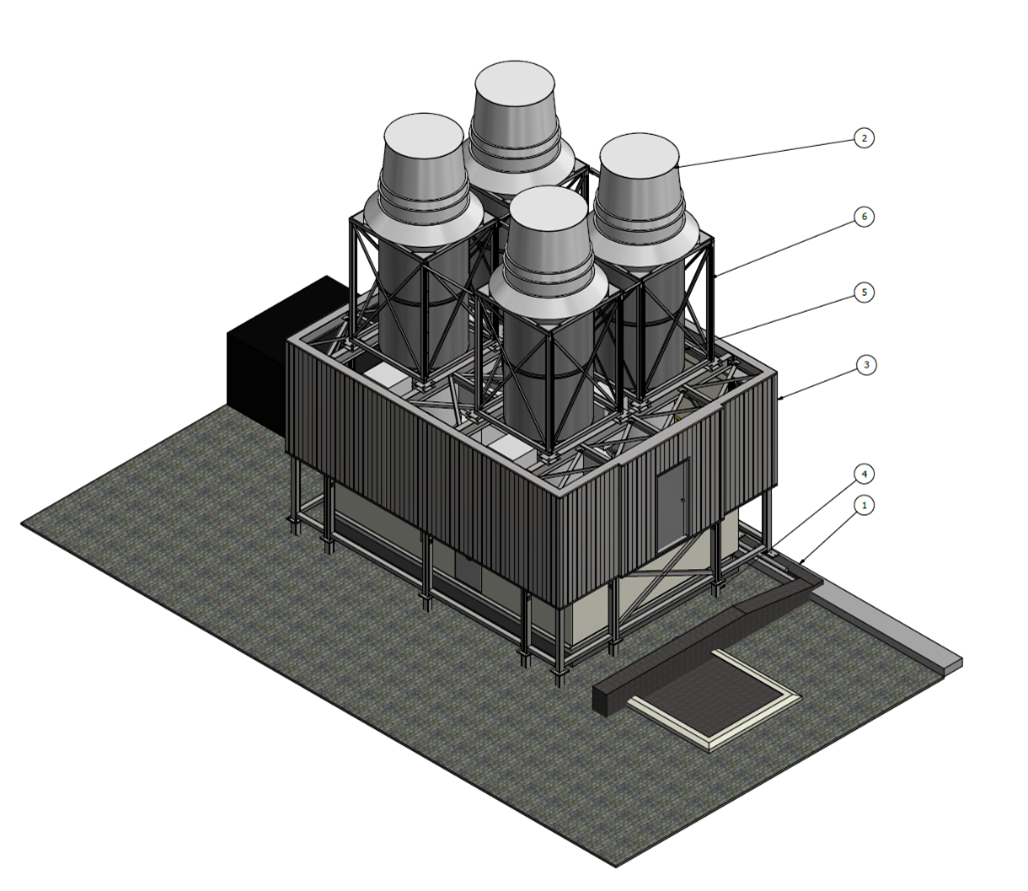

The project would include an upgrade of the building’s laboratory exhaust system, comprising four roof-mounted high plume exhaust fans situated on top of the 10-storey building.

What they didn’t count on was a mechanical noise challenge that could result in potentially costly non-compliance fines and even a facility shutdown. Renovation plans would need to be adjusted quickly to address the problem, while staying as close to project timelines and budgets as possible.

The Challenge

Following the commissioning of this high plume fan system, it was discovered that commissioned sounds levels failed to comply with a key Ontario regulatory ordinance (MOECC NPC-300). As such, a retrofit noise abatement solution was required.

Enter the Parklane team. We were engaged by the university to deliver several key services including:

- Detailed design of all noise control componentry including four 144” long inline circular silencers (with aerodynamic core bullet design) and a 120” high full perimeter acoustic barrier to mitigate fan casing noise. This included an architectural cladding panel on the façade of the barrier

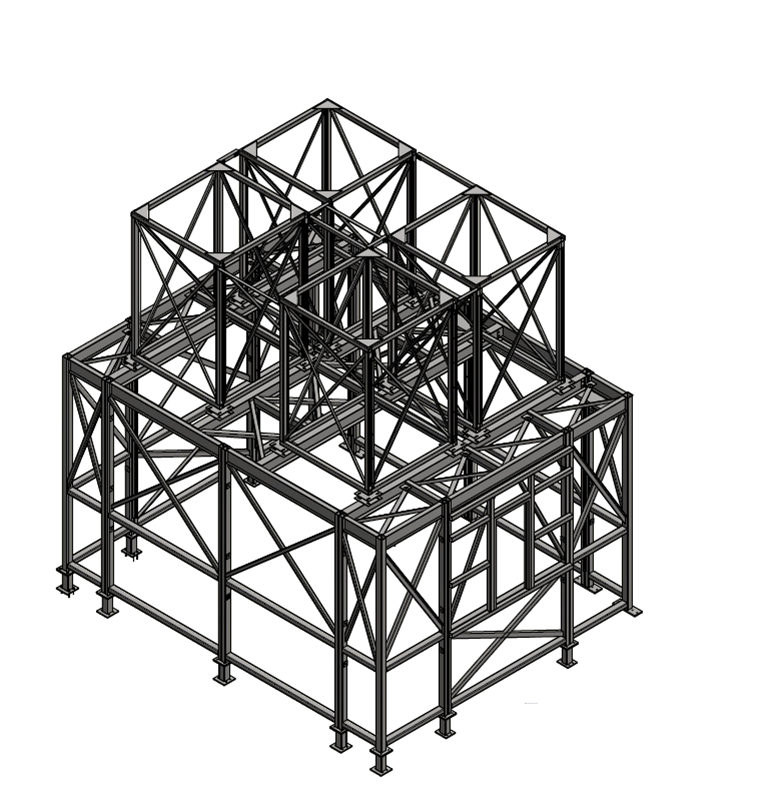

- Detailed design of an independent support structure for all acoustic components (40’ total structure height from top of roof)

- Fabrication of all components in our manufacturing facility

- Complete turnkey installation and on-site coordination

The project presented some unique hurdles that required our team to develop distinctly creative solutions. They included:

Aero-acoustic challenges—The design intent of a high plume fan system is to extend the ‘plume height’ of exhaust gases by way of accelerating airflow. This effectively eliminates the need for excessively large stacks.

Noise emissions stemming from high plume fan arrangements are typically the greatest at the ‘exhaust tip’ of the equipment, requiring inline silencing between the fan and the dilution nozzle. Critical design considerations must be taken into account to reduce sound levels without impacting the vertical throw of exhaust air.

This fan set required extensive acoustic mitigation, thereby requiring the aero-acoustic design to be made as efficient as possible.

Structural restrictions—In addition to the weight of the inline silencers (42” ID, 144” long), an independent structural support assembly was required to accommodate a full perimeter acoustic barrier. The acoustic barrier was needed to shield casing-radiated noise off of the fan casing. But doing so created excessive wind loads that needed to be transferred into the roof structure.

A base building structural review revealed that special care had to be taken when loading the roof. The existing concrete roof girders were already near capacity with the addition of the new fan system. Similarly, no additional loading could be transferred to the new rooftop equipment and/or plenum.

Site coordination—As a construction project with multiple active trades, site coordination was critical to get the job done safely and to the necessary specifications. Our team managed multiple site coordination considerations that were highly complex:

- Botterell Hall is directly adjacent to Kingston General Hospital, creating distinct challenges with road closures and pedestrian traffic control

- The high plume fans service critical lab activity, removing the option of a complete shutdown of the fans during installation

- Given this was still considered to be part of the original project, Parklane needed to coordinate with various project stakeholders to ensure seamless implementation of the solution including:

- Owner / facility staff

- General Contractor

- Equipment Supplier

- Mechanical Engineer

- Structural Engineer

- Architect

- Roofing Contractor

Aesthetic restrictions—As one of the tallest buildings on campus and in clear view from street level, the acoustic solution needed to align aesthetically with the existing fan set and the building façade.

Functional considerations—Because the entire fan system required complete acoustic shielding, the final design needed to accommodate clear access for future maintenance.

The Solution

We supplied four inline bulleted silencers that were installed in between the fan discharge and the dilution nozzle. The core bullet was aerodynamically optimized to reduce pressure drop and introduce greater laminar flow through the body of the silencer. This resulted in zero impact to the vertical plume height created by the system.

Structural Restrictions

Our team worked with the base building engineer to come up with an independent support frame and stub column configuration that properly transferred the wind and dead-loads from the silencer/barrier system to the reinforced roof girders. A complete moment frame was developed to limit critical loads being transferred into the roof.

Precise installation was critical. So, we coordinated a 3D metrology team to assist with the stub column installation. A series of remote sensors were placed along the interior beam centre lines. Parklane’s 3D structural model was then traced on-site to ensure load transfer points were situated precisely over top of the roof beams.

Site coordination

We coordinated with the client, the general contractor and City of Kingston throughout the process to arrange trades on site, as well as managing crane and freight logistics, and necessary road closures/traffic control, all in a short time frame. The complete on-site installation and site coordination was completed by our in-house team.

Our approach to minimizing shutdown time

To drastically limit crane time on site, the entire structural and acoustic solution was designed in a modular fashion. The acoustic barrier system was pre-integrated to the new substructure to eliminate on-site field assembly. The circular silencers came pre-fabricated inside a support frame, which could then be hoisted as one piece to the roof and installed in a fraction of the time required using traditional methods. All components were mechanically connected together to eliminate any on-site field welding.

We coordinated the installation so that no more than two fan sets were shut down at any given time, allowing the univeristy to keep critical lab spaces in operation.

The modular system deisgn combined with Parklane’s site coordination expertise limited the total install time to two weekends.

Aesthetics

To ensure the final system blended into the existing building façade, the perimeter acoustic barrier was finished with an architectural cladding panel colour matched to a similar product used on the building penthouse. The silencers were factory painted to match the OEM fan set components.

Functional considerations

Complete service access was maintained to fan motors and shutoffs. We also included an external service platform to access the top of the fan plenum.

The Result

Despite difficult weather conditions and a demanding schedule, Parklane was able to deliver an acoustically compliant solution which adhered to the structural, mechanical, architectural and functional requirements of the system and the facility. We did it by leveraging our systems and process to ensure a high-precision installation process without error. Perhaps most importantly, the Parklane team was able to work with the client to maintain facility operations throughout the installation.

It’s another example of our multi-disciplinary working to deliver an ideal project outcome, in this case for one of Canada’s most important research facilities.

Click here for more Parklane client success stories.