A Custom Silencer Case Study

Botterell Hall at Queen’s University

Botterell Hall at Queen’s University in Kingston, Ont., is home to the school’s Centre for Neuroscience Studies and plays host to advanced heart, stroke and cancer research. A decision was made to upgrade the mission-critical laboratory’s exhaust system, comprising four roof-mounted high plume exhaust fans situated on top of the 10-storey building. Soon after, it was discovered that commissioned sounds levels failed to comply with a key Ontario regulatory ordinance (MOECC NPC-300). A retrofit noise abatement solution was required.

University Lab Building

High Plume Exhaust Fan noise control

Using dissipative silencers and a modular acoustic barrier to mitigate noise from laboratory exhaust fans

The Project Facility

A University lab building located in a high traffic area

The Noise Source

Laboratory High Plume Exhaust Fan – Axial Fans with Discharge Dilution Nozzles

The Solution

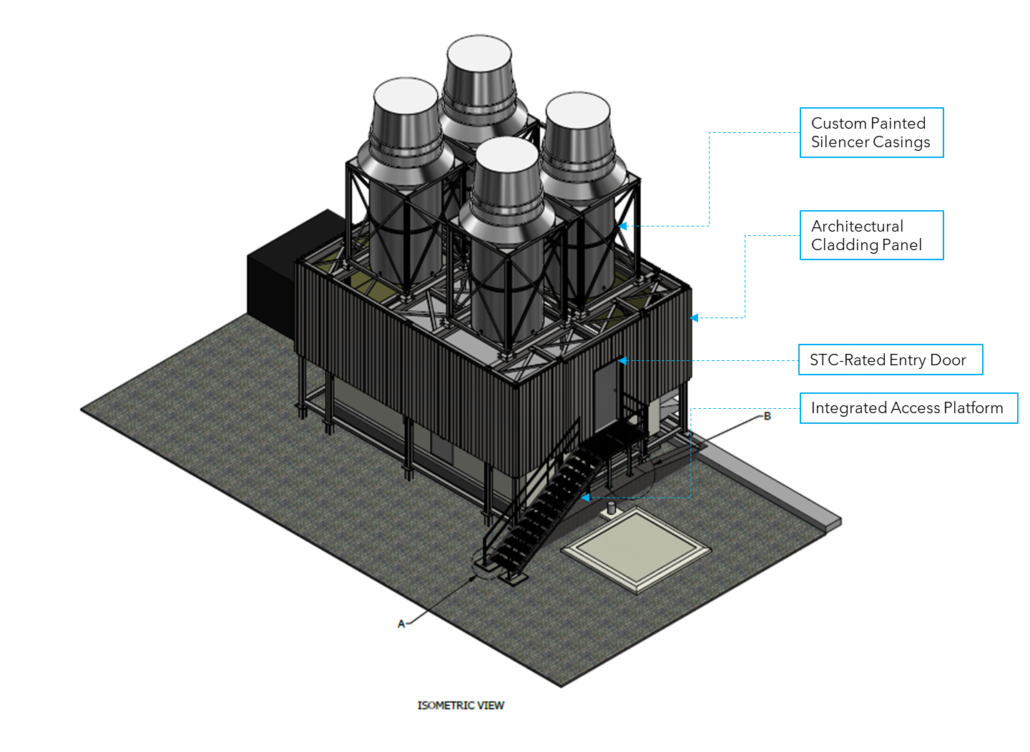

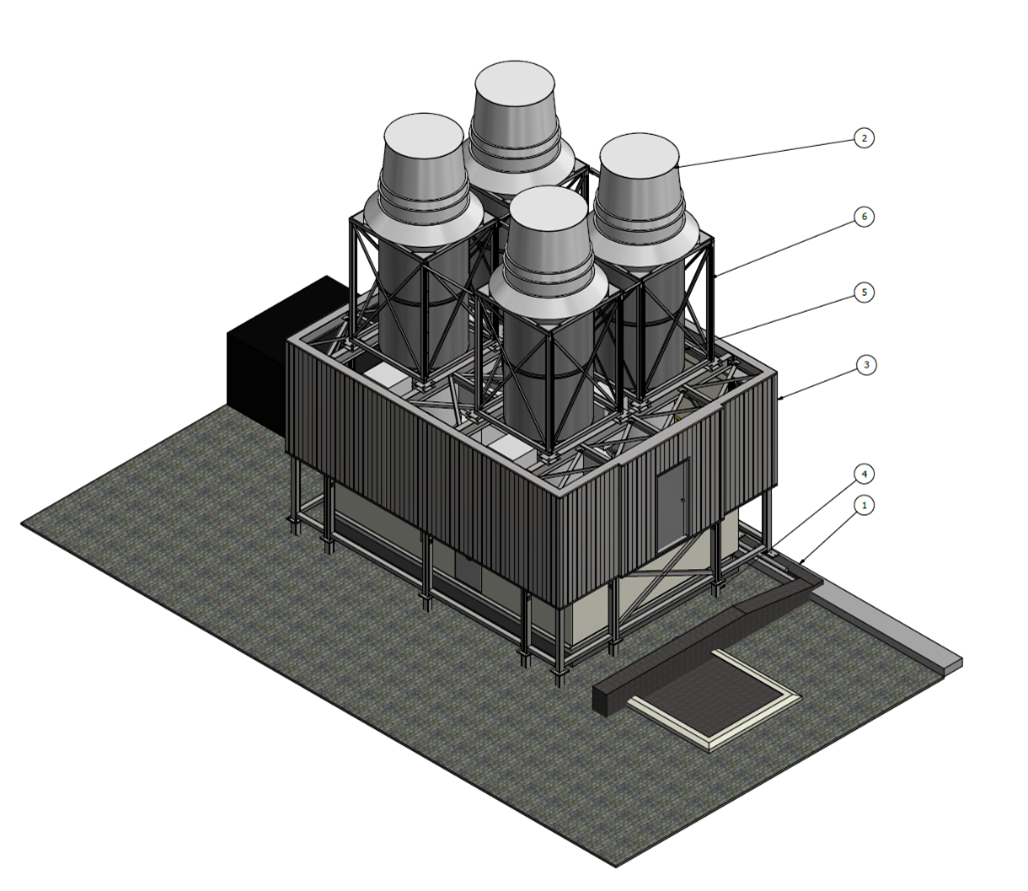

PMA Circular HPF Silencers

PMA AcoustaMod Sound Barrier System

The Project Team

Owner – Queen’s University

General Contractor – Pomerleau

Acoustic Consultant – O2E Environmental Consultants

Reason for Mitigation:

Provincial ordinance; Compliance with local regulatory limits for exterior noise emissions

Project Challenges

Aero-acoustic Challenges

Noise emissions stemming from high plume fan arrangements are typically the greatest at the ‘exhaust tip’ of the equipment, requiring inline silencing between the fan and the dilution nozzle. This fan set required extensive acoustic mitigation, thereby requiring the aero-acoustic design to be made as efficient as possible.

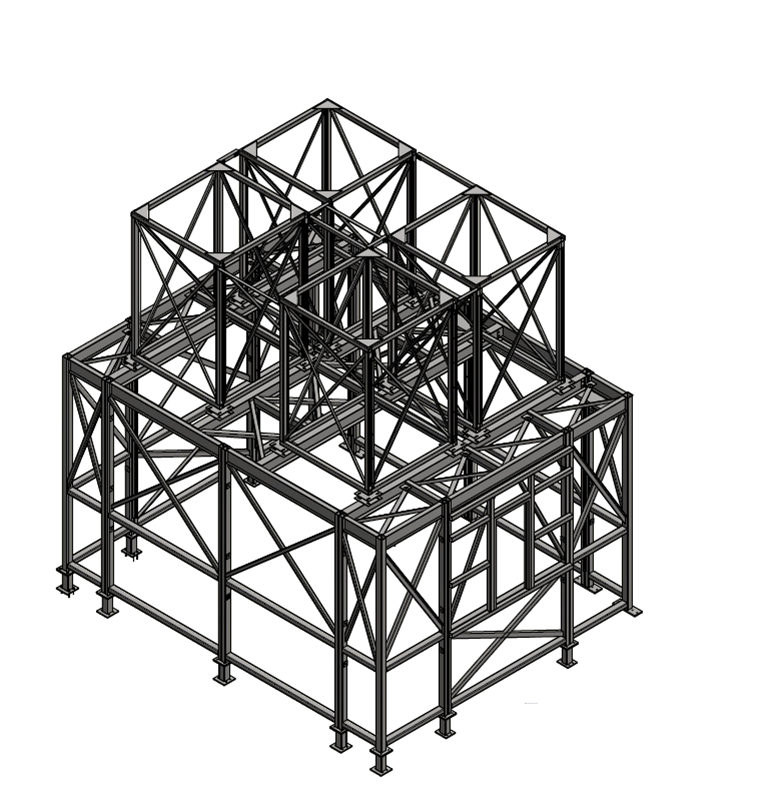

Structural restrictions

In addition to the weight of the inline silencers (42” ID, 144” long), an independent structural support assembly was required to accommodate a full perimeter acoustic barrier. The acoustic barrier was needed to shield casing-radiated noise off of the fan casing. But doing so created excessive wind loads that needed to be transferred into the roof structure.

Site coordination

Aesthetic and functional considerations

Project Solution

Design

Structural Restrictions

Installation

Site coordination

Downtime Minimization

Aesthetics

Results

Despite difficult weather conditions and a demanding schedule, Parklane was able to deliver an acoustically compliant solution which adhered to the structural, mechanical, architectural and functional requirements of the system and the facility. We did it by leveraging our systems and process to ensure a high-precision installation process without error.

Read the full story

View our blog post for the full story of how we helped Queen’s University achieve full regulatory compliance at Botterell Hall.

Let's work together

Contact a member of our team now to find out how Parklane can help provide an effective, customized solution to your organization’s noise control challenges.