VIRS Products

Spring Mounts

Our spring mount vibration control product line includes unhoused, housed and restrained spring mounts, along with seismic mounts and restraints, accessible spring mounts, thrust restraints and air springs.

Seismic Mounts & Restraints

Air Springs

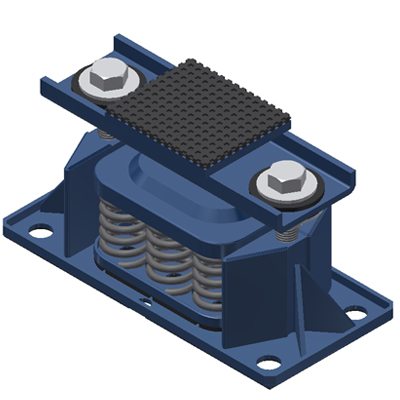

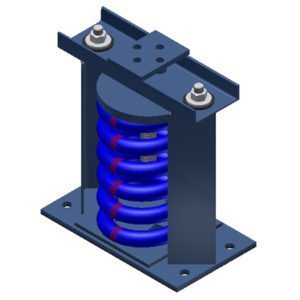

Unhoused Spring Mounts

Our spring isolators are free-standing and laterally stable, featuring a molded neoprene cup or 1/4” (6mm) neoprene acoustical friction pad between the baseplate and support. All of our product submittals include spring diameters, deflection, compressed spring height and solid spring height. Our unhoused spring mounts are all type SLF.

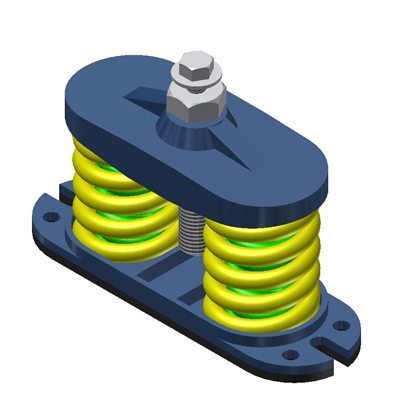

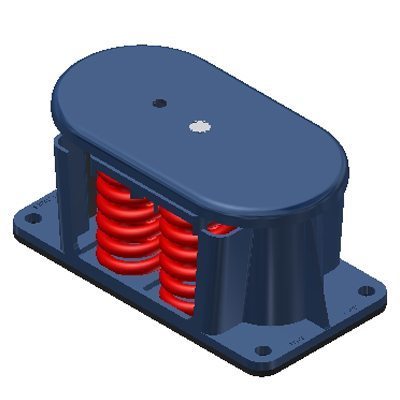

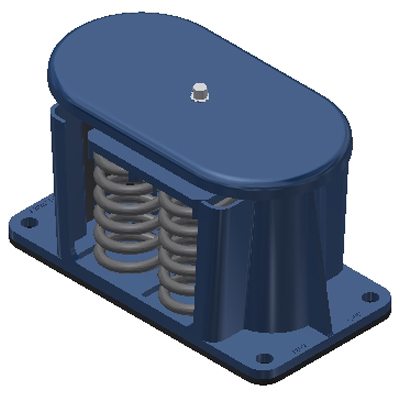

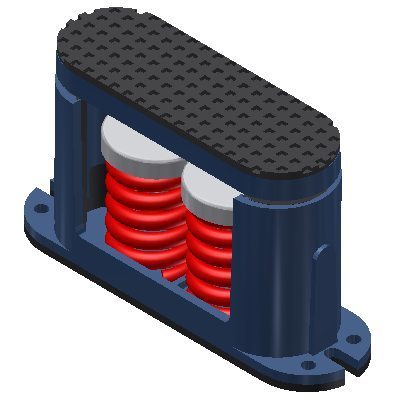

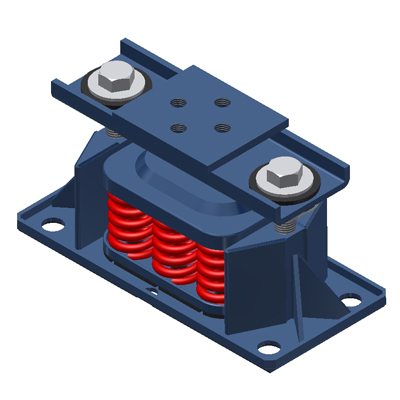

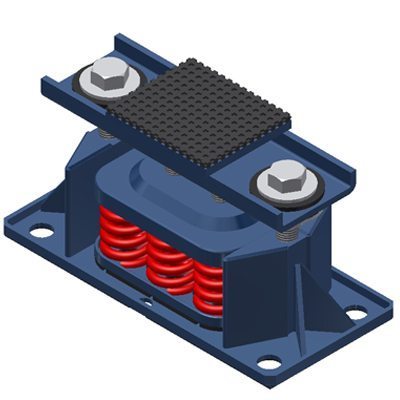

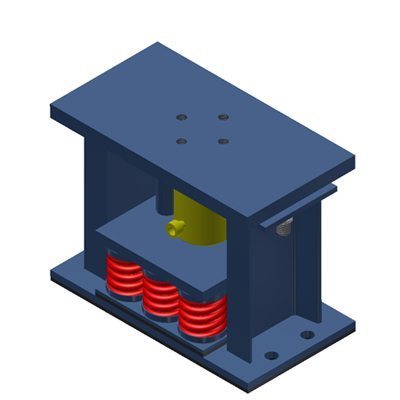

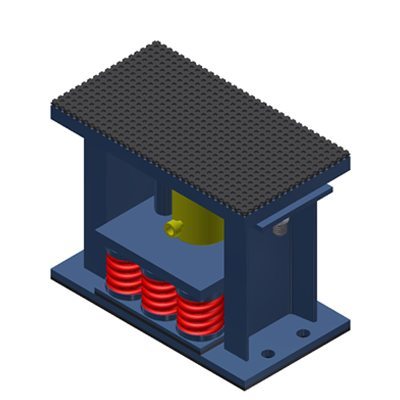

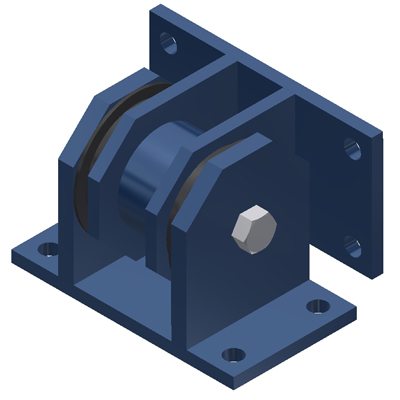

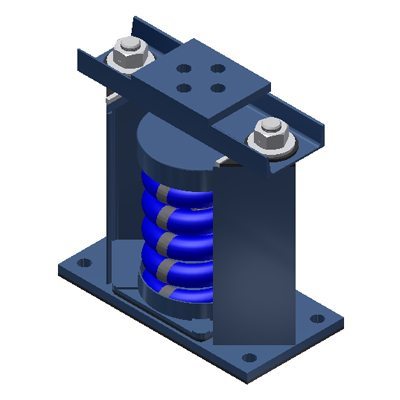

Housed Spring Mounts

Our Type ‘C’ spring mounts are designed to address the full scope of your vibration challenges. As a fully packaged solution, they deliver peak performance in environments where a high-yield mount is required to dampen low natural frequencies, such as when applied to light concrete or wooden floors. Our semi-circular neoprene sponge inserts help prevent contact between upper and lower semi-steel castings. Our non-adjustable inserts are recommended for air applications below compressors, centrifugal fans, air handling units and other constant-frequency vibration sources.

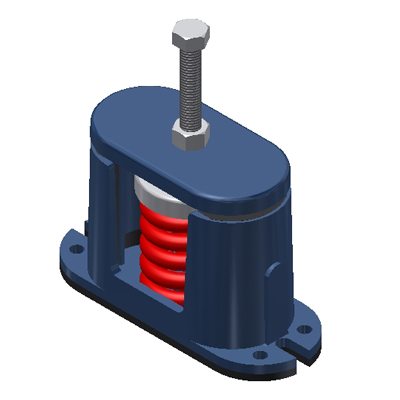

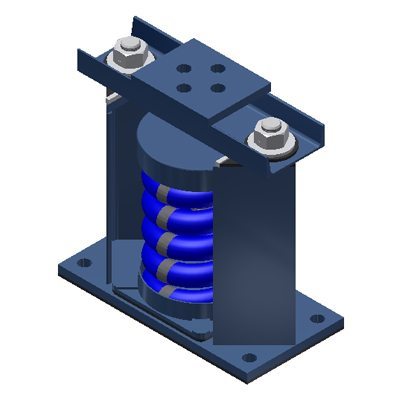

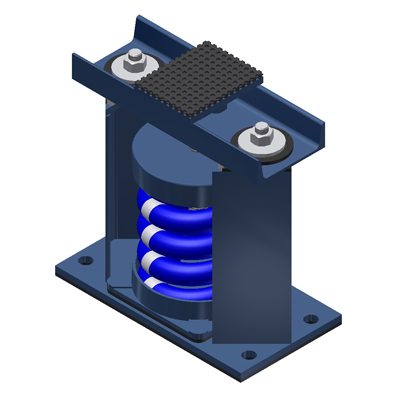

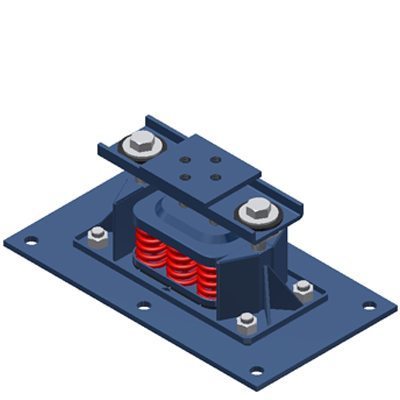

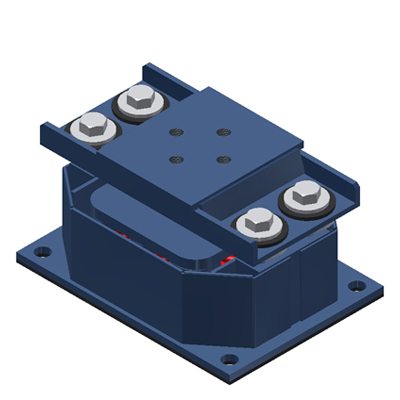

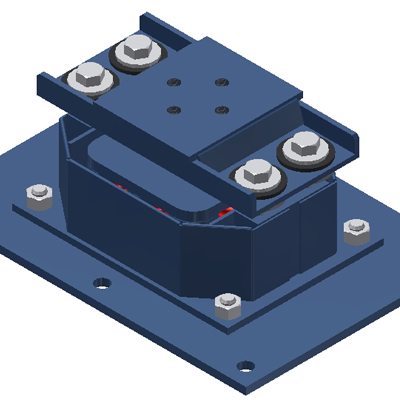

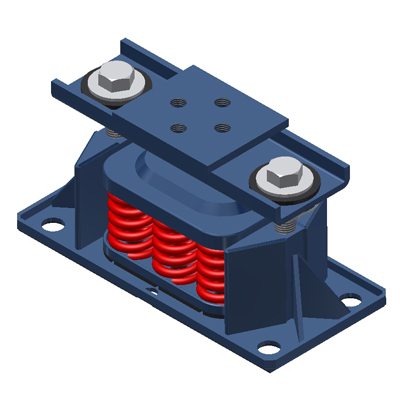

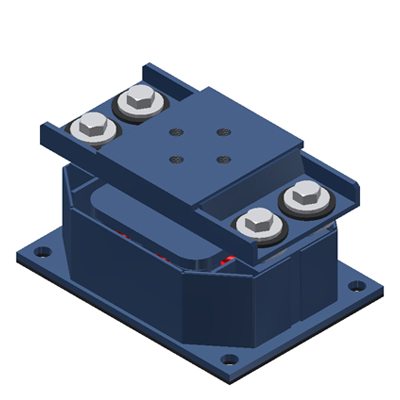

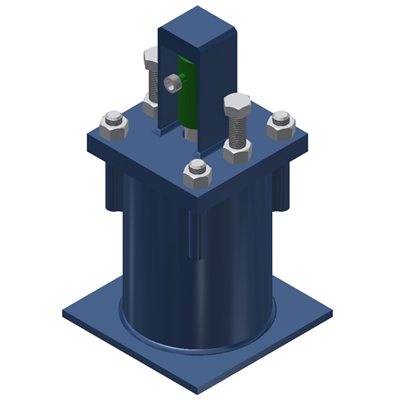

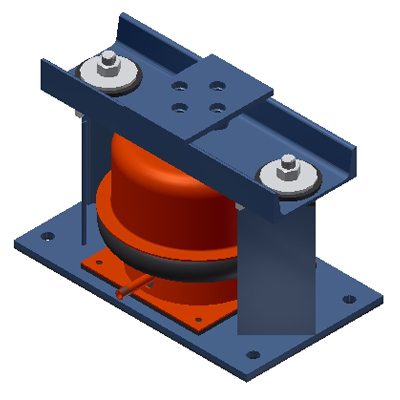

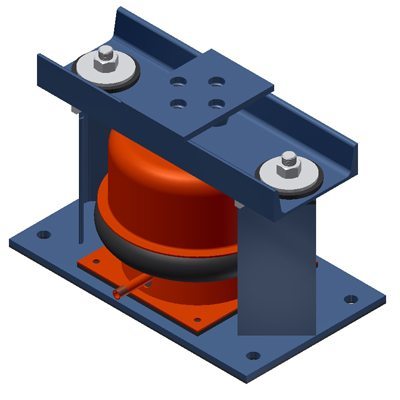

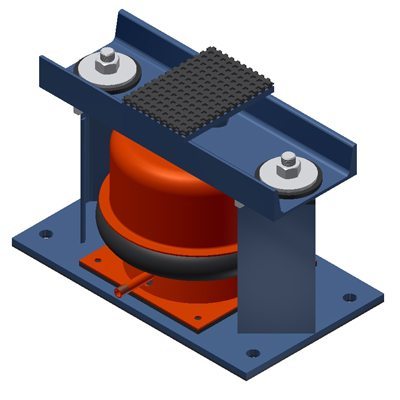

Restrained Spring Mounts

Our restrained spring mounts are designed to be used with SLF mountings in a rigid housing that employs vertical limit stops to minimize spring extension after weight is removed. Internal isolation pads are required for use with all housings, which are designed for peak seismic force resistance.

Seismic Mounts & Restraints

Our mountings, hanger-cables and snubbers are designed to resist seismic force across environments and specifications. Many of our mountings and hangers follow the same design as those used in static locations, but are designated by numbers in our Selection Guide rather than using letters to distinguish between applications.

Accessible Spring Mounts

Careful attention must be paid to mass and air gap considerations when introducing secondary walls to complete a building envelope. For that reason, poured concrete or concrete block walls should be of a similar density to the floor that supports them. Block joints should be filled with mortar and walls painted to help ensure airtight construction. We recommend resting these walls on a floating floor’s perimeter to enable the floor isolation system to support the surrounding walls. As an alternative, an isolated wall can be supported on a structural slab with continuous LDS pads.

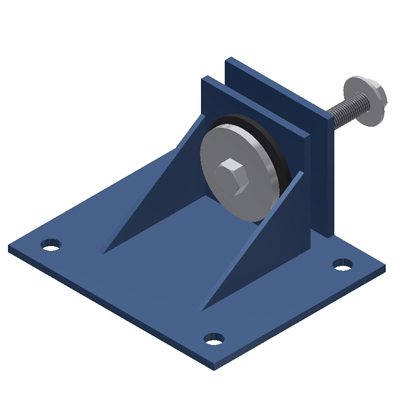

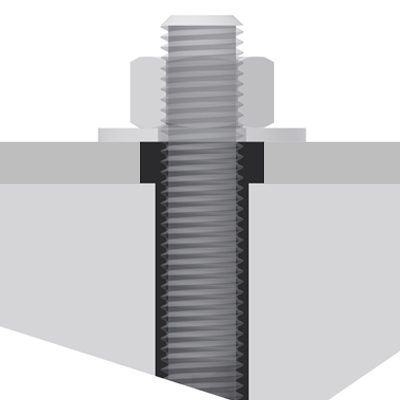

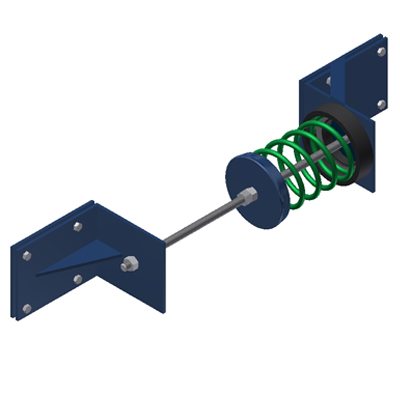

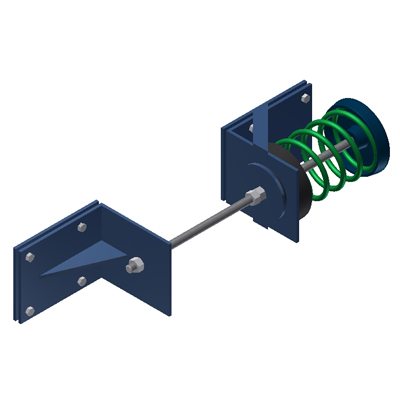

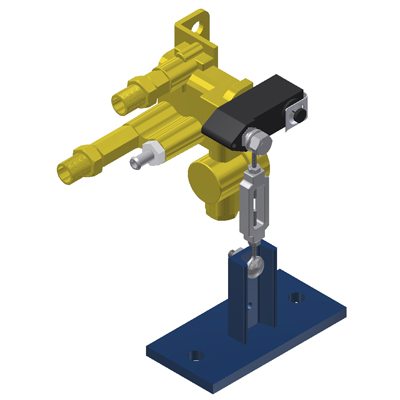

Thrust Restraints

Our horizontal thrust restraints are designed to consist of a spring element in series with a neoprene molded cup, with the same deflection as specified for the mountings or hangers. The assembly is furnished with a single rod and angle brackets for attachment to both the equipment and the ductwork or the equipment and the structure. All horizontal restraints are to be attached at the centerline of thrust and symmetrical on either side of the unit.

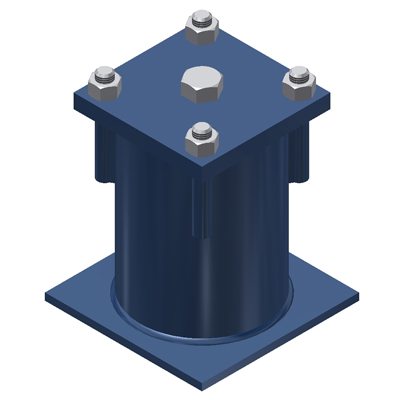

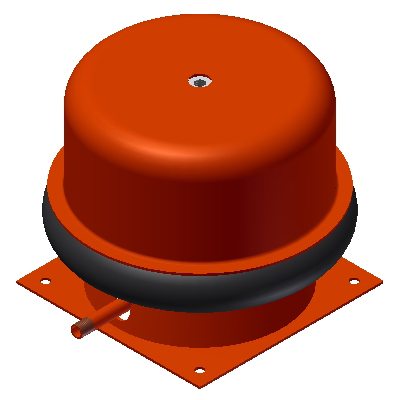

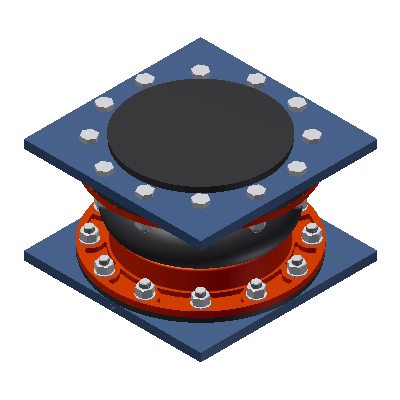

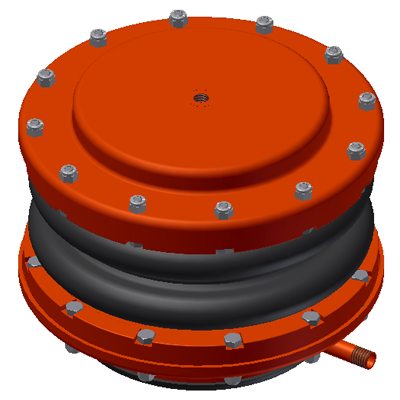

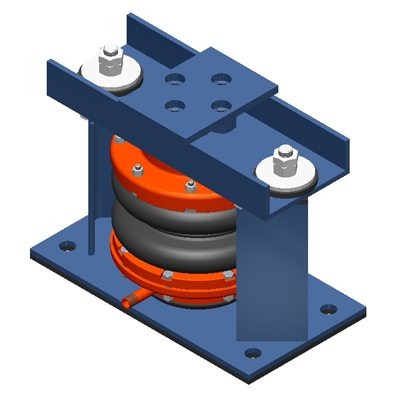

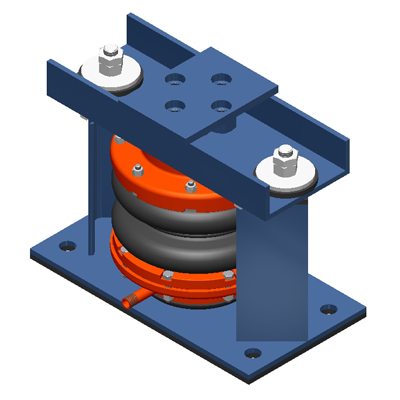

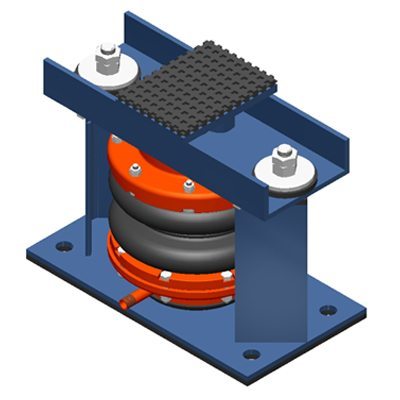

Air Springs

Our air springs feature upper and lower steel sections connected by a replaceable flexible nylon reinforced neoprene element. Air spring configurations feature multiple bellows to achieve a maximum natural frequency of 3 Hz. Our air spring systems are designed to work in connection to a building control air or supplementary air supply. They come equipped with three leveling valves for leveling within plus or minus 3 mm. Submittals should include load, natural frequency and damping tests performed by an independent lab or acoustician.

Let's talk about your project needs

We offer a comprehensive line of vibration control products and engineering services.

Contact a member of the Parklane team today to learn how our turnkey and agile Parklane360 service process is built to address the full scope of your vibration-control requirements.

Parklane

(905) 844-5020

Solving your complex challenges

By taking a fully integrated approach to every project, we leverage our team’s engineering expertise, a commitment to quality product manufacturing and a service-focused delivery model to help mitigate non-compliance risk and deliver the results you expect—every time.

Learn more about: