VIRS Products

Mounts & Pads

We provide a full range of mounts, pads, bushings and wedge jacks to meet your vibration mitigation needs.

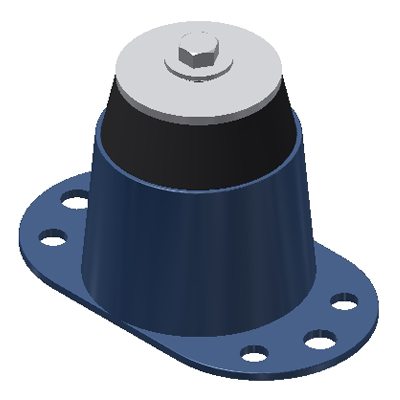

Bushings

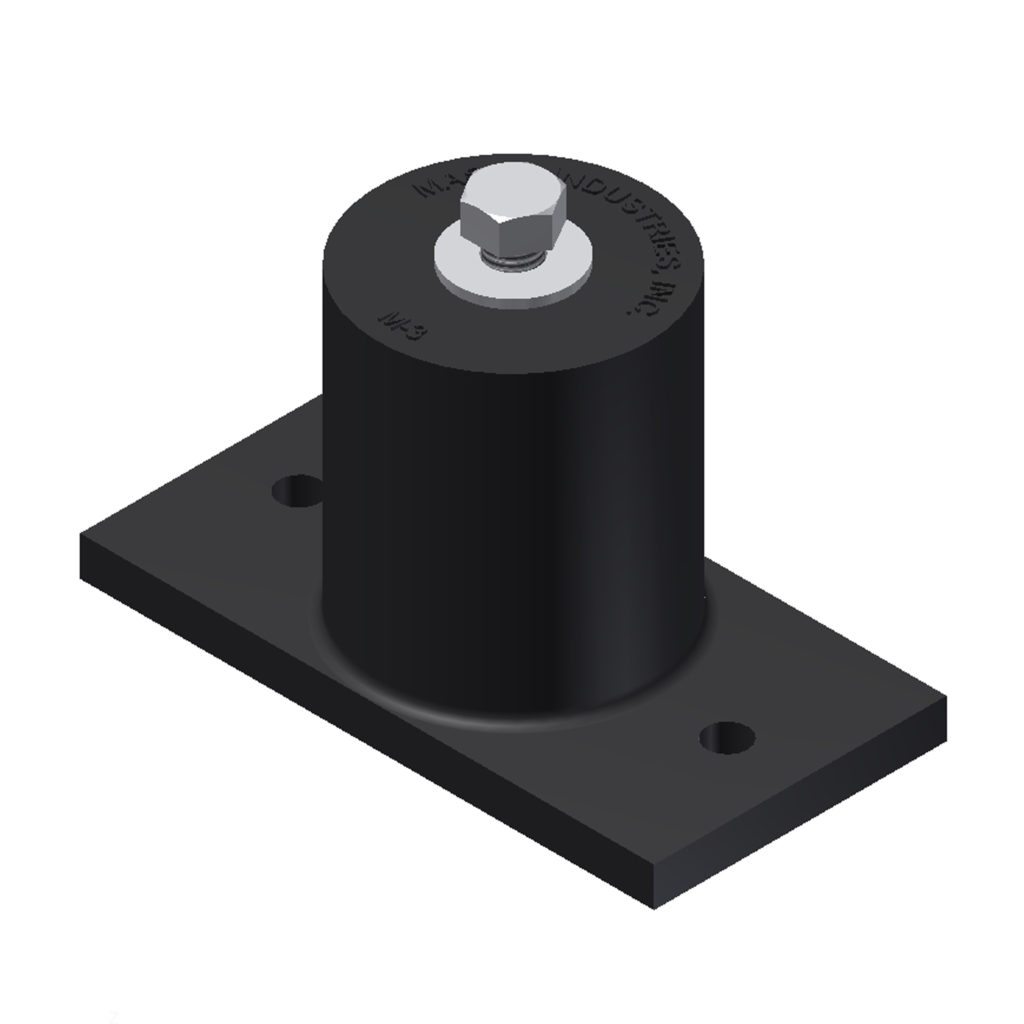

Neoprene Mounts

Because most rubber mountings produced until the 1950s were designed to handle load in shear, failure was common due to degradation between rubber and metal components over time. Our neoprene mounts are designed to deliver adequate cushioning, even in circumstances when overloading occurs.

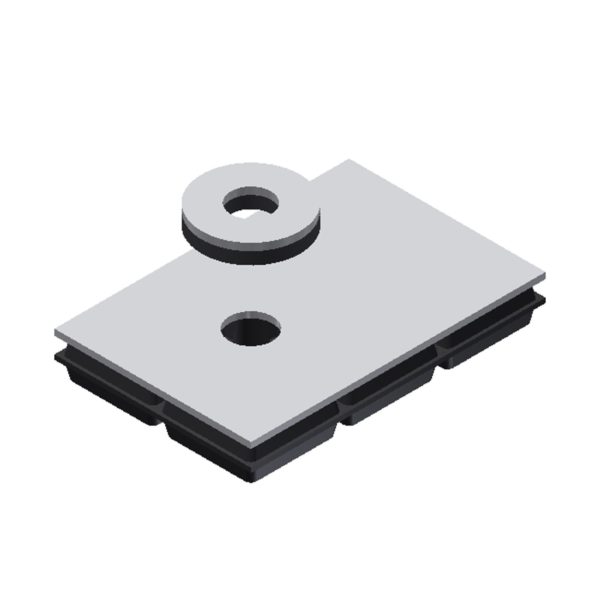

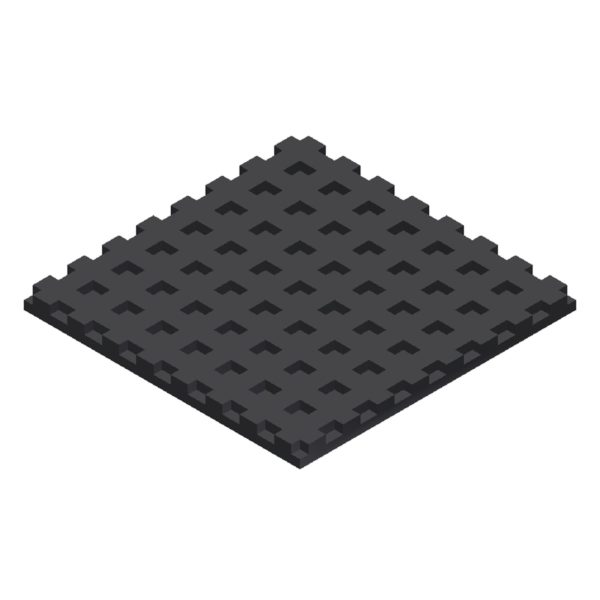

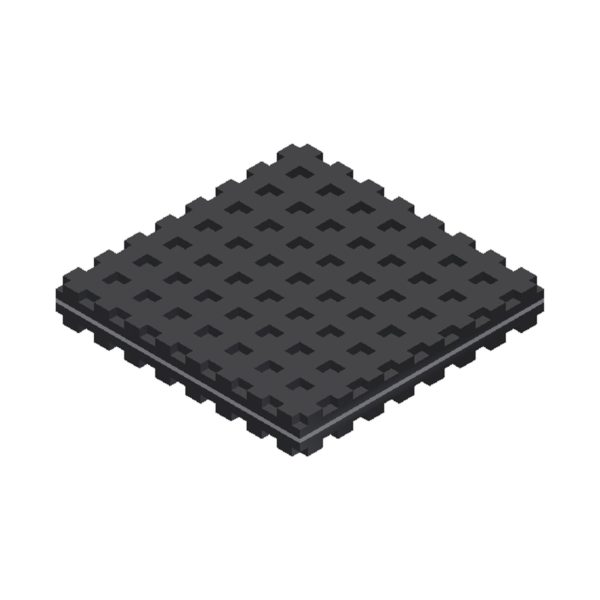

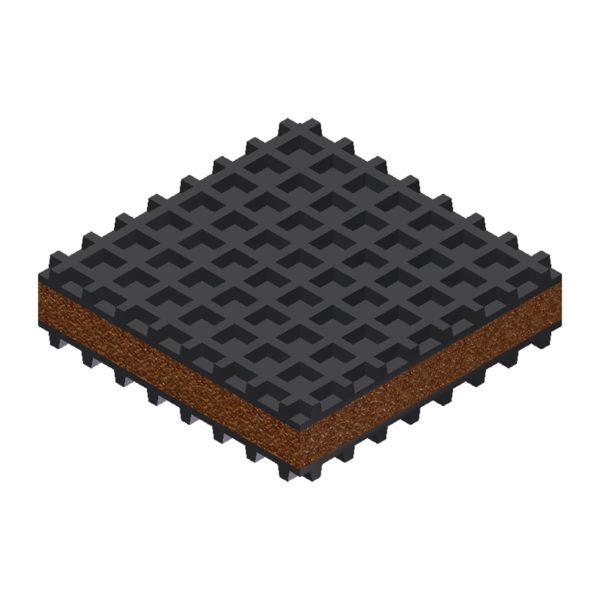

Neoprene Pads

Like neoprene mounts, our neoprene vibration control pads are applied in situations where shock, noise and high-frequency vibration mitigation is required—often in industrial or institutional settings where mechanical equipment sits directly on concrete slab.

Bushings

Our bushings are built to minimize vibration between components, while allowing movement as needed to ensure proper functionality of a component or a larger mechanical system. Their design is intended to provide the maximum degree of flexibility and reliability, ensuring you can achieve the goals of your vibration-control project.

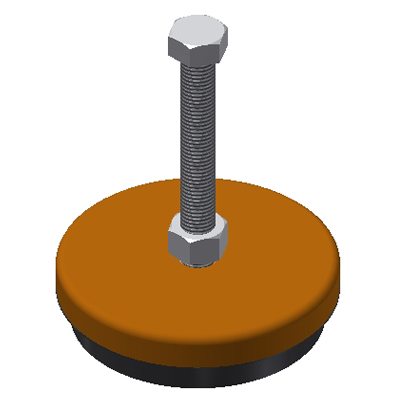

Wedge Jacks

Wedge jacks provide rigid support (after adjustment) in situations where leveling is required. Our jacks feature mating parts with spherical seats that allow automatic adjustment for up to 7° of transverse compensation for uneven floors. The wedges can be moved by turning the adjustment bolts.

Our jacks are furnished without pads when used strictly for leveling, or with 1/2″ (13mm) thick oil resistant pads to provide friction and vibration isolation across all other applications. Our three-piece jacks have a through hole for bolting, ensuring that equipment moves only vertically during adjustment.

Let's discuss your project needs

We offer a comprehensive line of vibration control products and engineering services.

Contact a member of the Parklane team today to learn how our turnkey and agile Parklane360 service process is built to address the full scope of your vibration-control requirements.

Parklane

(905) 844-5020

Solving your complex challenges

By taking a fully integrated approach to every project, we leverage our team’s engineering expertise, a commitment to quality product manufacturing and a service-focused delivery model to help mitigate non-compliance risk and deliver the results you expect—every time.

Learn more about: