Gravity Barriers

Introducing the Parklane Gravity Barrier™ system—an innovative self-supporting solution designed to transform the way you approach rooftop structures. This advanced system minimizes or eliminates the need for rigid connections to your building’s roof structure, ensuring both safety and efficiency.

Gravity Barriers

The Parklane Gravity Barrier™ system is a self-supporting solution that can be designed to eliminate or drastically reduce any rigid connection to a building’s roof structure. During installation, this eliminates any disruption into the occupied space below. Post-installation, it prevents future risk of roof leaks.

- Residential buildings

- Commercial Buildings

- Institutions

- Manufacturing

Key Features

Designed with flexibility in mind, our Gravity Barriers™ offer an effective solution for achieving rooftop screening that preserves the structural integrity of your building while still meeting aesthetic and functional needs.

Fully Customizable Design

Tailored to meet the unique requirements of any project, regardless of size or scope, the Gravity Barrier™ can be designed to adhere to any footprint requirements and geometric configurations.

Effective Modular Solutions

Our standardized modular frame design allows for expedited installation timelines and mitigates the risk of delays.

Seamless Installation

Our expert installation team works diligently to ensure that setup is efficient and prioritizes minimal disruption, allowing your operations to continue without interference.

Maintains Structural Integrity

Once installed, the Gravity Barrier™ system significantly mitigates the risk of future roof leaks, extending the lifespan of your roof structure and reduces potential maintenance costs.

Success Stories

Explore more on how Parklane’s proprietary Gravity Barrier™ solutions can align perfectly with your project’s vision and specifications.

Industry Leaders

Whether working with industry, acoustic engineers and consultants, or contractors, we’re committed to providing turkey solutions to noise challenges—no matter the size or scope.

Speed & Flexibility is our strength

Parklane Gravity Barriers™ are the most easily-deployed and structurally sound product on the market. Fully flexible and self-supporting, our roof screening system is the natural choice for the life of your buildings

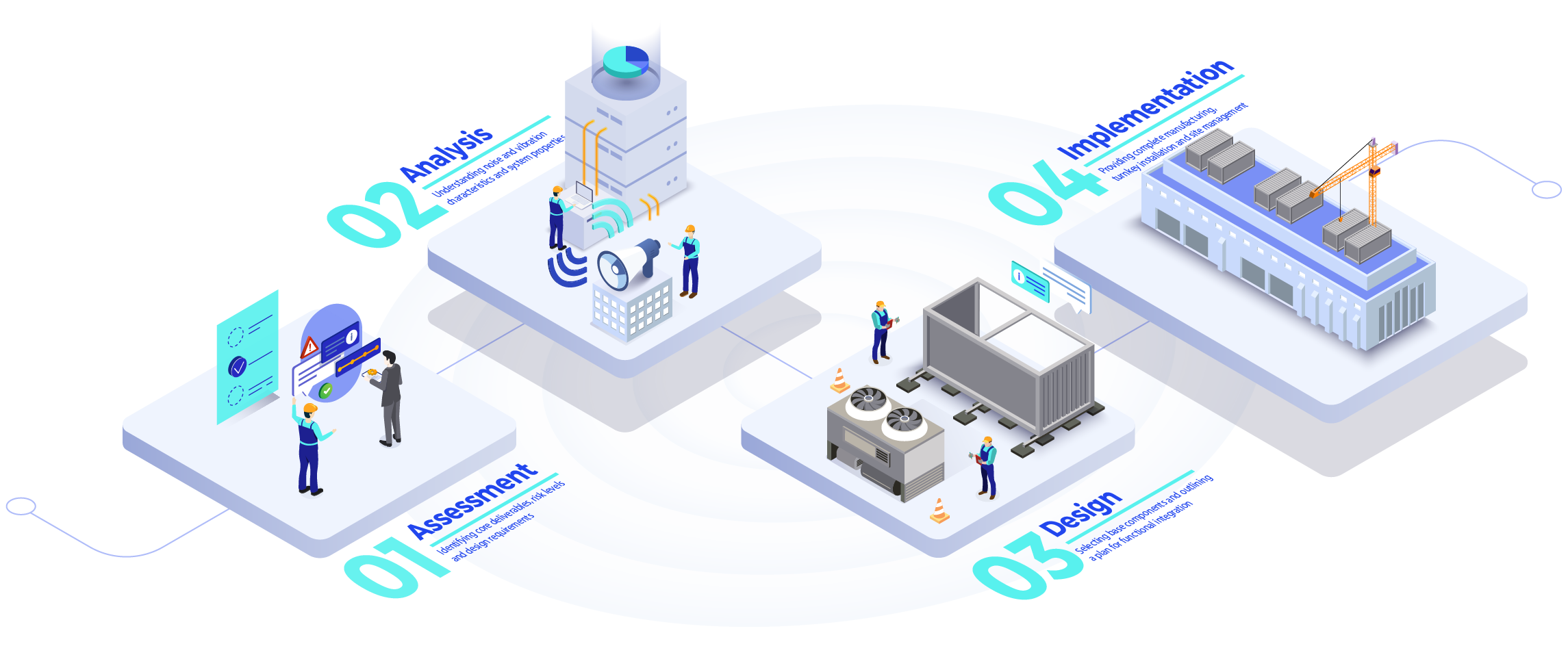

Solving your complex challenges

By taking a fully integrated approach to every project, we leverage our team’s engineering expertise, a commitment to quality product manufacturing and a service-focused delivery model to help mitigate non-compliance risk and deliver the results you expect—every time.

Learn more about:

Learn More About Our

At-Source Attenuation Solutions

Download our comprehensive brochure to learn more about our Gravity Barriers™, their design process, and their key features.

Because mechanical noise issues should never be a distraction

Contact a member of our team now to find out how Parklane can help provide an effective, customized solution to your organization’s noise control challenges.