A Custom Generator Enclosure case study

Taunton Light Plant

Peak Power Shaving Generators

Diesel Generator noise control (retrofit solution)

Applying a resiliently mounted CLD acoustic wall system to mitigate an underperforming generator enclosure.

The Project Facility

Public utility station

The Noise Source

Peak Power Shaving Natural Gas Generators

The Solution

Resiliently Mounted Acoustic Wall System

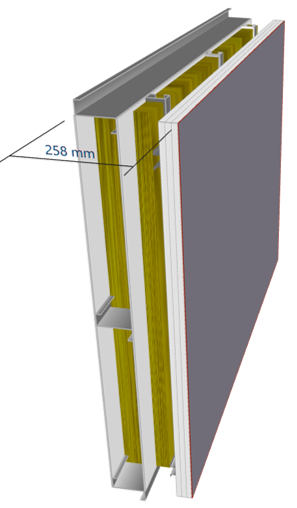

PMA-3-HTL-CLD acoustic panel

The Project Team

Public Utility

Equipment OEM

Acoustic Consultant – Acentech

Reason for Mitigation:

State ordinance; Compliance with local regulatory limits for exterior noise emissions

Project Challenges

Acoustic Performance

Through the detailed analytical efforts of the acoustic consultant engaged on the project, it was discovered that the acoustic deficiencies were primarily caused by insufficient transmission loss in the enclosure casing around the generator set. Inadequate mass (i.e., to attenuate lower frequencies) and vibratory transmission into the wall panels were additional causal factors.

Site Fitment

Our team would need to design an at-source solution that would address the shortfall in acoustic performance, while overcoming the major cost and functionality concerns. Integrating this type of solution would entail precise field measurements enabling us to work around the various openings and appurtenances affixed to the unit.

Time

Project Solution

Collaborative design and Installation

The project team would construct and install a built-up vibration isolated acoustic wall panel on the east and south wall of the fourth generator. An external steel stud wall was constructed in front of the existing enclosure, then pinned back to the enclosure structure using a grid of neoprene wall mounts. The new acoustic panel was laid into the decoupled stud wall and finished with an architectural cladding system.

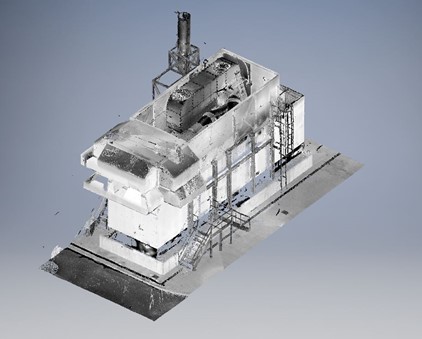

Cloud Modeling

Instead of attempting to manually capture all of the small details on this large system to address the site fitment issues, we used long-range laser scanning to generate a detailed point cloud model of the entire equipment set. This virtually eliminated the need for extensive on-site measurement. All detailed design was completed by Parklane’s in-house engineers and CAD technicians, using the 3D-point cloud model created in this single scanning process.

Logistics

Results

By moving to this innovative at-source approach, we avoided the addition of foundations or any major substructure. This alleviated site congestion concerns, and reduced the cost of the project to about 25 per cent from the original proposal. Through extensive collaboration with the acoustic consultant, we were able to successfully reduce the Taunton plant’s noise emissions to within local ordinance limits in 10 days, achieving our project objectives efficiently and with no impact on the plant’s operations.

Read the full story

Find out how we helped the Taunton Light Plant achieve regulatory compliance.

Let's work together

Contact a member of our team now to find out how Parklane can help provide an effective, customized solution to your organization’s noise control challenges.